Description

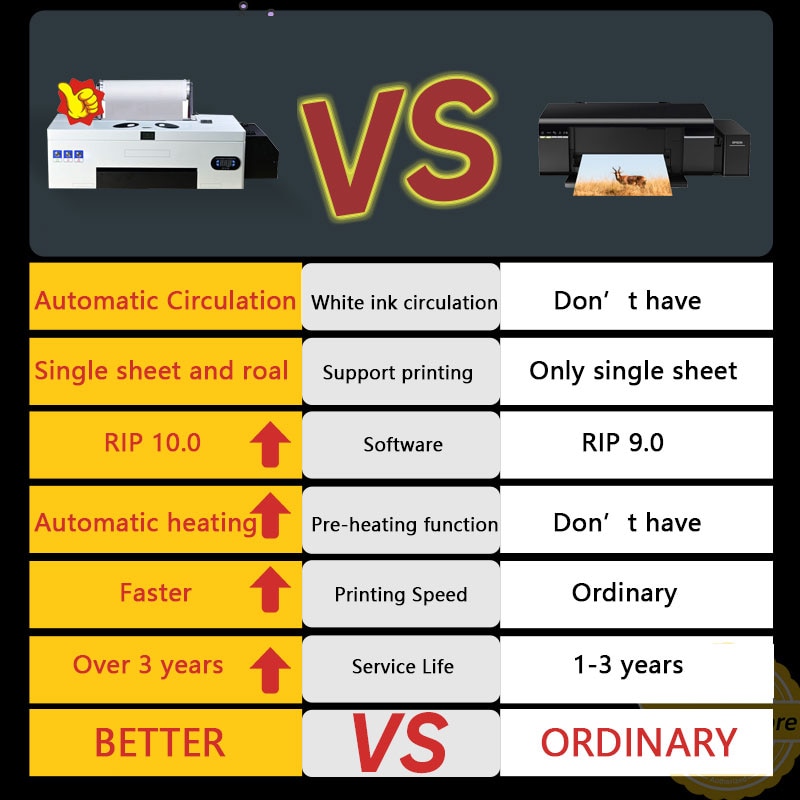

This item contains the Procolored R1390 DTF PRINTER, plus Software and accessories you will need to get started in your own DTF business! (40% FASTER SPEEDS)!

Includes:

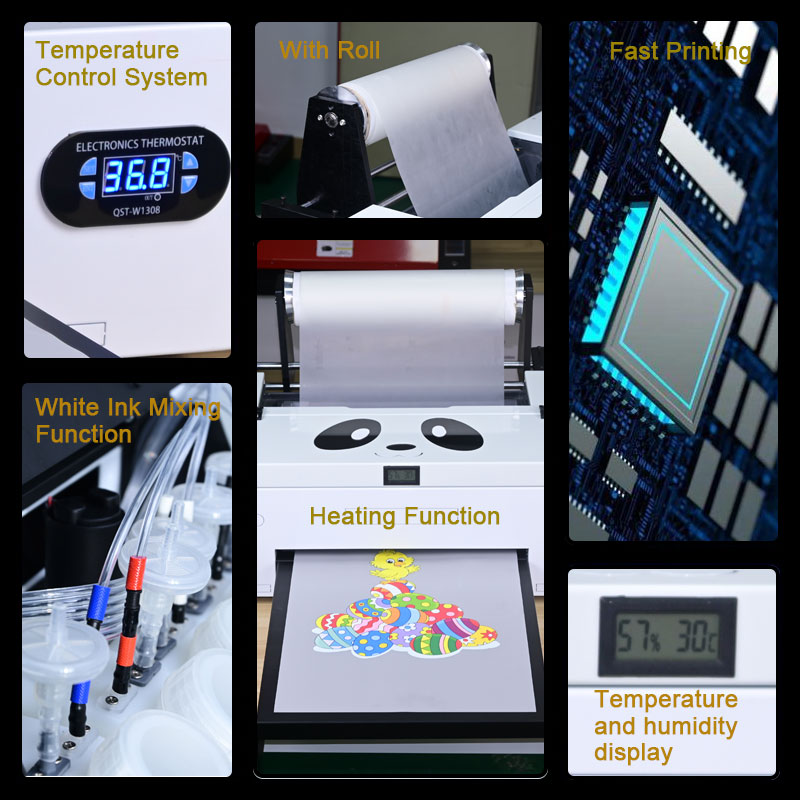

Procolored A3 DTF Printer (prints up to A3+ Size DTF Sheets 30cm*42cm )

DTF Sheet Exit Tray – to guide the Transfer Sheets out of the printer after they have been printed and avoid the paper getting buckled or caught by the rollers. Prevents film curling and ink smearing

External Ink Tank System (no cartridges needed)

DTF Software (capable of single-pass white and color printing)

UnLimited aftersale support (China time 9:00-12:00 ,13:30-6:00 Every Monday to Saturday)

(Full teaching sessions focused on your success)

Perfect for entry level customers who want to get into the DTF business.

What's Included in the package :

DTF Inks 5*250ml + 250ML Protection Liquid (need more can just order from us )

DTF Protection Device*1

Software *1

Teaching Video*1

DTF Transfer Films : 100pcs width 30cm*length 42cm Or 1 Roll 30cm*100M ( Depends u choose sheet type or Roll type )

DTF Powder Heat Oven (to cure the powder to the printed sheets) just choose the option include it .

What's NOT Included but you may need:

DTF PreTreat Powder (aka Transfer Powder, sold separately)

Windows 7 or higher Computer (PC) with an available USB port

Heat press for finishing (curing) the final print to your garment – We recommend a 16x20s heat press

Humidifier (to keep the humidity above 40% in the print room) – recommended

Maintenance / Cleaning Accessories

* This is a DIY type item which requires practice and patience to hone your skills. Just like any product or business venture, you can't expect it to make you money out the box – you need to work at it and hone your skills. DTF is not a complicated technology, but it does have a learning curve. There are many resources online (videos, forums, groups) that can provide you with guidance, tips and advice – and we will recommend and provide some of these resources to our customers. The price of this item includes Unlimited onboarding of approximately (priceless )! We will guide you on how to use the printer and software. This printer willl accept A4 sheets, A3 sheets and A3+ sheets up to 13" x 19, maximum print area is 13" x 16".

DUE TO HIGH DEMAND, there is a 2 week estimated Delivery time . Orders are shipped on a first ordered, first shipped basis. Contact us for expedited requests or custom color options if required.

This is a modified Epson printer, modified to work with DTF. It does not come with the original Epson printer warranty, but it does come with the Procolored 3 years limited warranty (except the parts touched with inks)to be free of defects in workmanship and materials.

BENEFITS OVER TONER TRANSFER & DTG TECHNOLOGY:

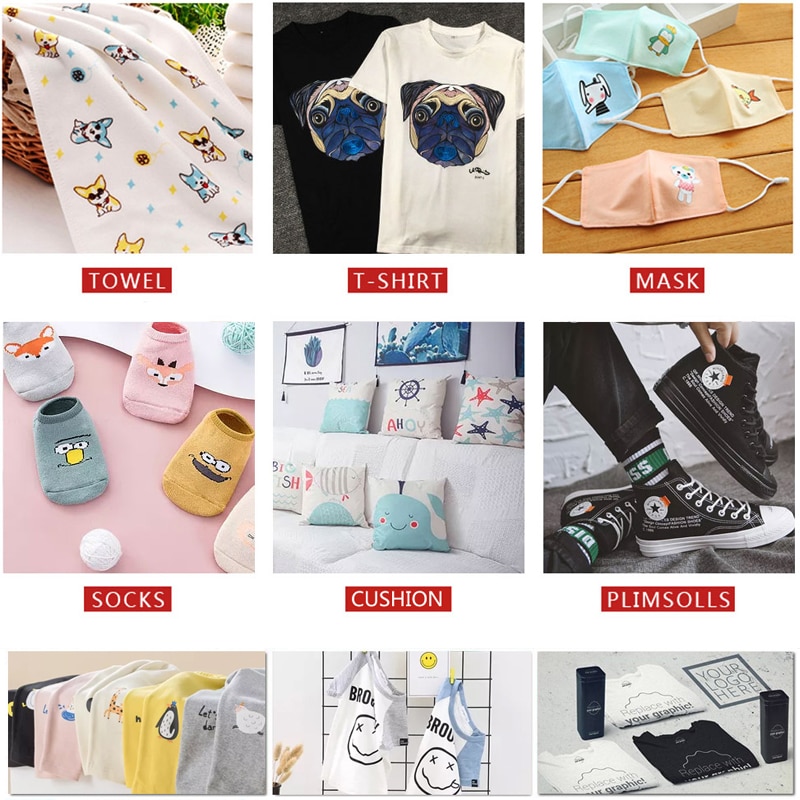

As compared to TONER TRANSFER technology , DTF offers a cheaper startup cost (approx 50% cheaper); cheaper supplies (cheaper ink and cheaper transfer sheets); easier software management; better photographic quality prints; and better feel to the hand. DTF also prints to both WHITE or BLACK (or dark) textiles, and is applicable to a variety of textiles including cotton, poly and more.

As compared to DTG technology , DTF offers a cheaper startup cost (approx 50% to 75% cheaper) and NO PRETREATMENT required (less cost and less user dependency), although you will require DTF PreTreat Sheets and DTF PreTreat Powder. The print quality and the feel of the printed textiles is very similar to DTG. The substrates that DTF will work on are much wider than DTG (DTG is mainly for cotton, but DTF will work on cotton, poly, 50/50 blends and more).

WARNING: WORK IN A WELL VENTILATED AREA and use Protective Equipment when working with DTF products and processes as fumes may be hazardous. DTF inks and film require a good humidity environment – over 40% humidity is highly recommended to minimize risk of ink clogs and film buckling.

Materials to be prepared for printing: DTF printer, oven, heat transfer machine, PET film, rubber powder

1.Pull the picture to be printed into the printing software of the printer, and then adjust the size and position of the picture to be printed for printing

2.Print mode setting: You can choose white ink printing, color ink printing, or white ink and color ink printing together

3.Note when printing: When you print, you need the printer on the front side of the PET film (the side with the rubber powder)

4.Coating rubber powder: evenly spread the prepared rubber powder on the PET film

5.Baking PET film: Put the PET film in the oven to bake the picture, the temperature is 110°, and the baking time is 150-180 seconds. When all the rubber powder on the pattern needs to be melted, it can be used.

6.To transfer the pattern to the T-shirt, first iron the clothes with a hot press, and then put the PET film on the clothes. The hot stamping temperature is 160°, and it needs to be pressed for 50 seconds.

Note: We prepare the USB for you in the package, and there are detailed installation videos and printing videos inside.

Reviews

There are no reviews yet.